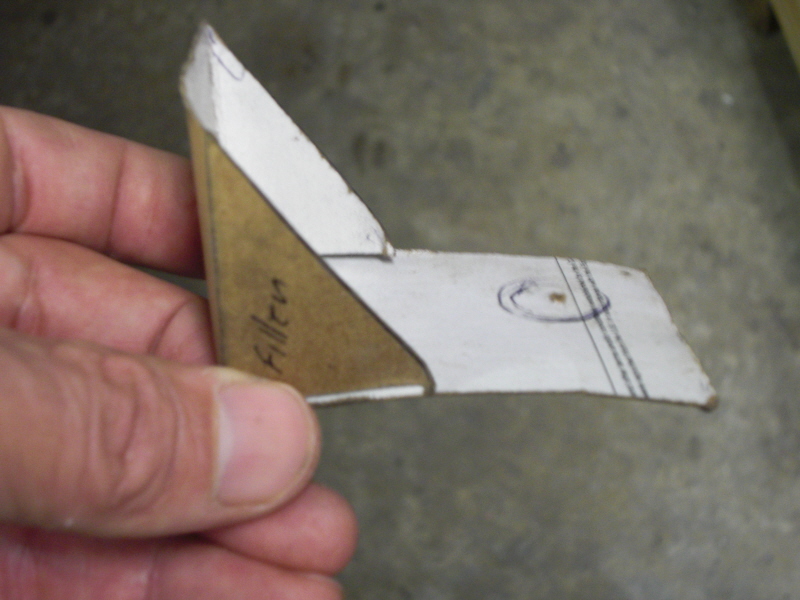

First I made a template from thin cardboard after taking many

measurements

This is what it looks like when it is folded and in position.

I laid it flat again on some sheet metal traced it and then cut one out

of sheet metal with a hand held manual

cutter and folded the metal (in a vice) just like the cardboard. Then

welded (mig) the folded tabs along the bottom to make a little sort

of.box.

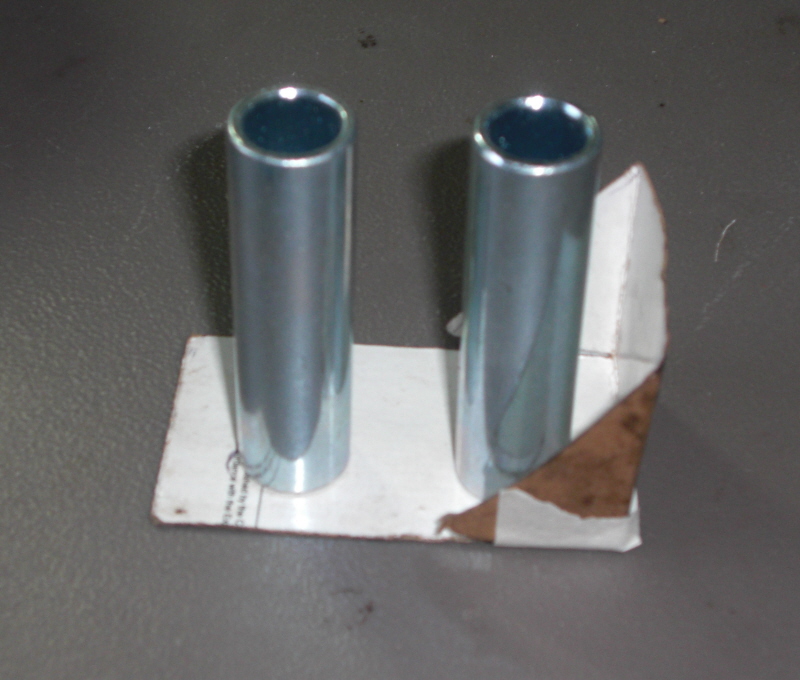

I made two. One for each side.

Then I mark the position to where the bolt holes will be and drill the

2 holes

in the sheet metal. The then tac welded two tubes centered over the

holes.

(Keep in mind this above picture

is for example only because the job was already done.)

The tubes are for the bolts to go through and they are there to prevent

all the sheet metal work from

collapsing and crushing when you tighten everything up to mount the

trans.

In this picture I am holding up the template in the position of how it

was welded next to the under-body location of where this new braket is

already made.

(Again, the job is already done it this picture, the front of the car

is the left side of the picture.)

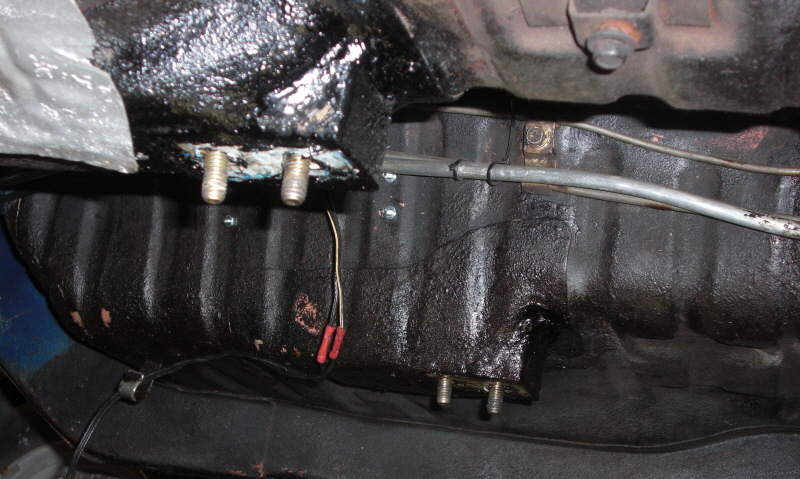

Another picture of the job done.

it is hard to see my welds because I undercoated everything after the

job was done.

The 4 studs you see are actually the long bolts I put in hanging down

from the inside of the car.

If you look close on the far side you can barely see one of the

original holes for the original trans on the left.

The front of the car is the left side of the picture.

Here is a picture of the boltheads and large washers I used.

I am pulling up the mat on the drivers side floor pan for the picture.

The top of the picture is the front of the car.

Hope this all helps. Thanks, Rick Dormoi

Back to

Toyhead

Auto Home Page